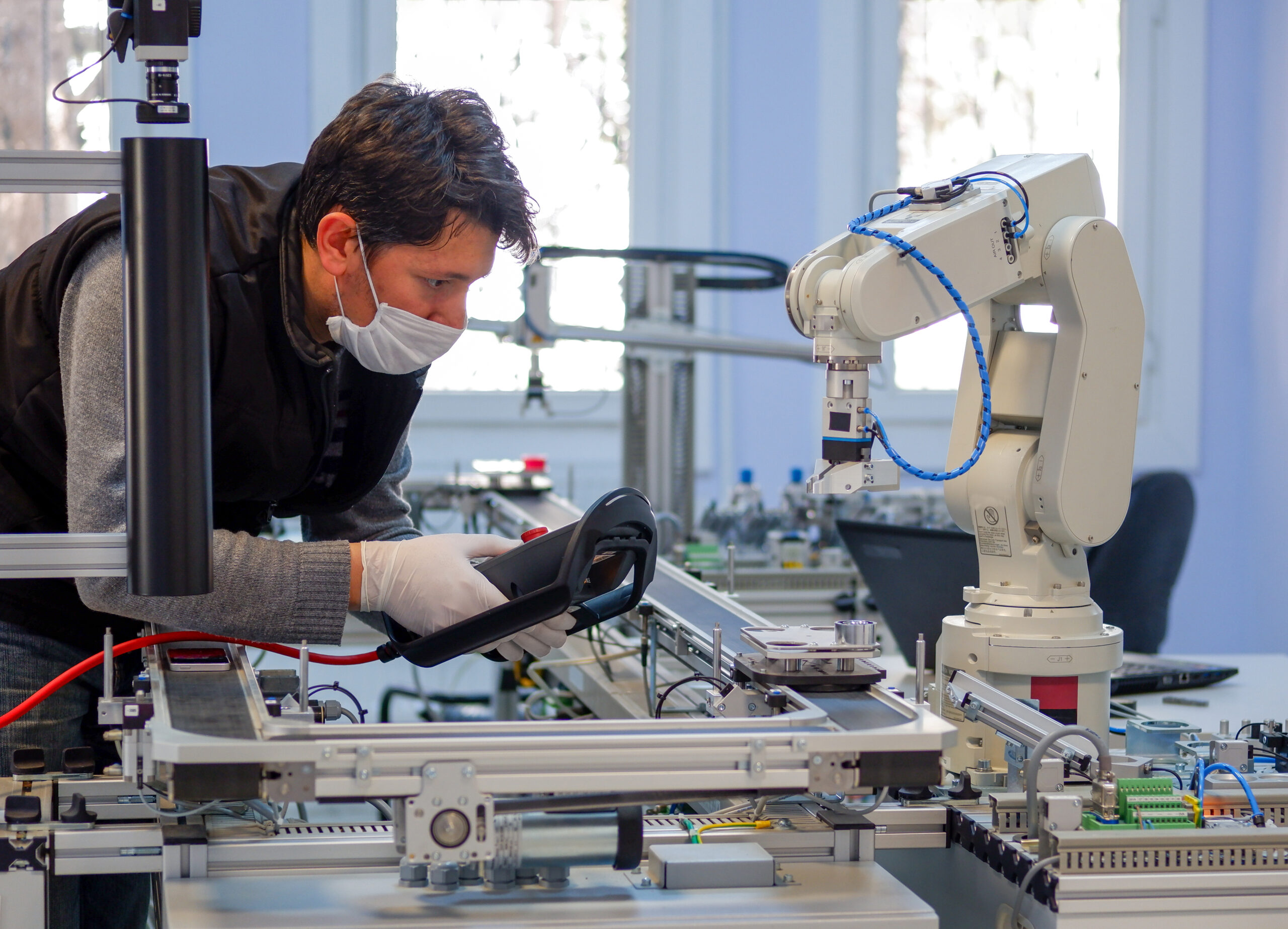

Industrial Robot Programming

Maximize uptime and quality with expertly programmed industrial robots. We deliver online and offline programming, cycle‑time optimization, and seamless integration with PLCs, vision, and safety—covering greenfield cells, retrofits, and continuous improvement projects.

- Offline programming (OLP) and simulation

- On‑site robot teaching and commissioning

- Vision, force sensing, and I/O integration

- Cycle‑time tuning and path optimization

- Documentation, training, and support

Core Capabilities

Reliable, maintainable robot code aligned with your safety, throughput, and quality targets.

Offline Programming

Build, simulate, and validate paths, tools, reach, and sequence in a virtual cell to shorten on‑site time.

Online Teaching

Precise point teaching, TCP/tool setup, frames, payloads, and robust recovery routines on the shop floor.

PLC & I/O

Handshake with PLCs, safety signals, grippers, weld guns, screwdrivers, and peripheral equipment.

Vision & Force

2D/3D vision guidance, part location, inspection, and force/torque feedback for compliant tasks.

Cycle Optimization

Path smoothing, blending, interference zones, and tool strategies to reduce takt time and wear.

Docs & Training

Backup sets, IO maps, recovery guides, operator training, and change management procedures.

Our Programming Process

We use a simulation‑first approach to reduce risk and ensure smooth startup on site.

- Define: Parts, tools, payloads, cycle targets, safety level, and IO.

- Simulate: Build virtual cell, reach/clearance checks, sequence, and timing.

- Program: Develop OLP or online code with recoveries and diagnostics.

- Test: Dry runs with PLC, safety validation, and interference zones.

- Commission: On‑site teaching, tuning, SAT, and operator training.

- Handover: Final backups, docs, and support arrangements.

Applications

Programming tailored to process needs and quality criteria across manufacturing environments.

- Pick‑and‑place, machine tending, and palletizing

- MIG/TIG/spot welding and laser applications

- Gluing, sealing, deburring, and polishing

- Packaging, case packing, and kitting

- Vision‑guided inspection and bin picking

Robot Brands

Experience across leading industrial and collaborative robot platforms.

FANUC, ABB, KUKA, Yaskawa Motoman, Kawasaki

Universal Robots, Doosan, Techman, Omron TM

Grippers, weld packages, screwdrivers, vision, force

EtherNet/IP, Profinet, Modbus, IO‑Link

Need Reliable Robot Paths and Uptime?

Share your parts, tools, and cycle targets—we’ll propose a programming plan and timeline.

Get a ProposalOther Services

Explore our full range of engineering solutions.