Advanced Simulation & Design Optimization

Validate and improve your products before they reach the shop floor. Our simulation team leverages Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) to predict real‑world behavior, identify risks, and guide design decisions that deliver higher performance at lower cost and shorter timelines.

-

- Structural, thermal, and dynamic FEA studies

- Fluid flow, heat transfer, and multiphysics CFD

- Parametric optimization and sensitivity studies

- Material, load, and boundary condition exploration

- Production‑ready recommendations and documentation

Finite Element Analysis (FEA)

Explore multiple design alternatives rapidly and quantify stress, strain, displacement, fatigue life, and safety factors under realistic loads. We use linear and nonlinear methods to reveal failure modes and areas for weight, cost, and reliability improvements.

Strength & Fatigue

Stress hotspots, fatigue life, and durability predictions.

Thermal Effects

Thermal loads, expansion, and thermal‑structural coupling.

Dynamics & Vibration

Modal, harmonic, random vibration, shock response.

Nonlinear Cases

Contacts, large deformations, and material nonlinearity.

Outcomes include clear design actions—geometry updates, material changes, or reinforcements—to hit performance targets with confidence.

Computational Fluid Dynamics (CFD)

Model fluid flow and heat transfer to optimize pressure drop, mixing, cooling, ventilation, and overall energy efficiency. Our CFD studies accelerate iteration while reducing reliance on costly physical trials.

Aerodynamics & HVAC

Flow distribution, drag reduction, ducting and ventilation.

Internal Flows

Pumps, valves, manifolds, and cooling channels.

Thermal Management

Electronics cooling and heat exchanger performance.

Multiphysics

Conjugate heat transfer and reacting flows where required.

We provide actionable recommendations to balance performance with manufacturability and cost.

Design Optimization

Turn insights into measurable gains. We run parameter sweeps, sensitivity analyses, and optimization loops to reach the best trade‑off across weight, stiffness, thermal performance, cost, and safety margins—aligned with your requirements and standards.

- Objective & constraint definition

- DOE and response‑surface modeling

- Topology, size, and shape optimization

- Manufacturability and cost constraints

- Final verification and handover

What You’ll Receive

Decision‑ready outputs that translate directly into design updates and production documentation.

Engineering Reports

Clear summaries with assumptions, methods, plots, and prioritized recommendations.

Updated CAD

Revised models/drawings reflecting optimized geometry and specifications.

Correlation & Validation

Test plans, acceptance criteria, and where needed, prototype validation guidance.

Industries We Serve

We support performance‑critical programs across sectors with strict reliability and compliance needs.

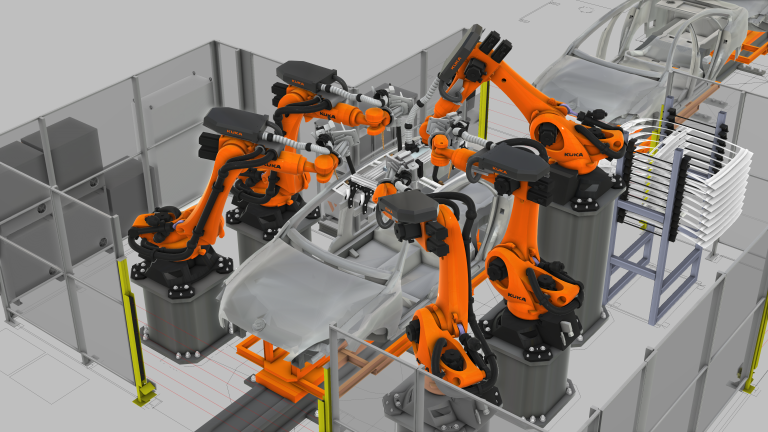

- Automotive & Off‑Highway

- Aerospace & Defense

- Energy & Utilities

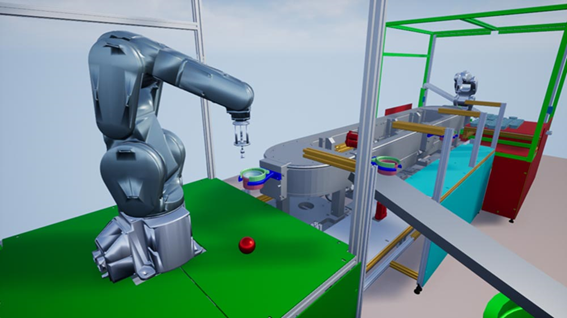

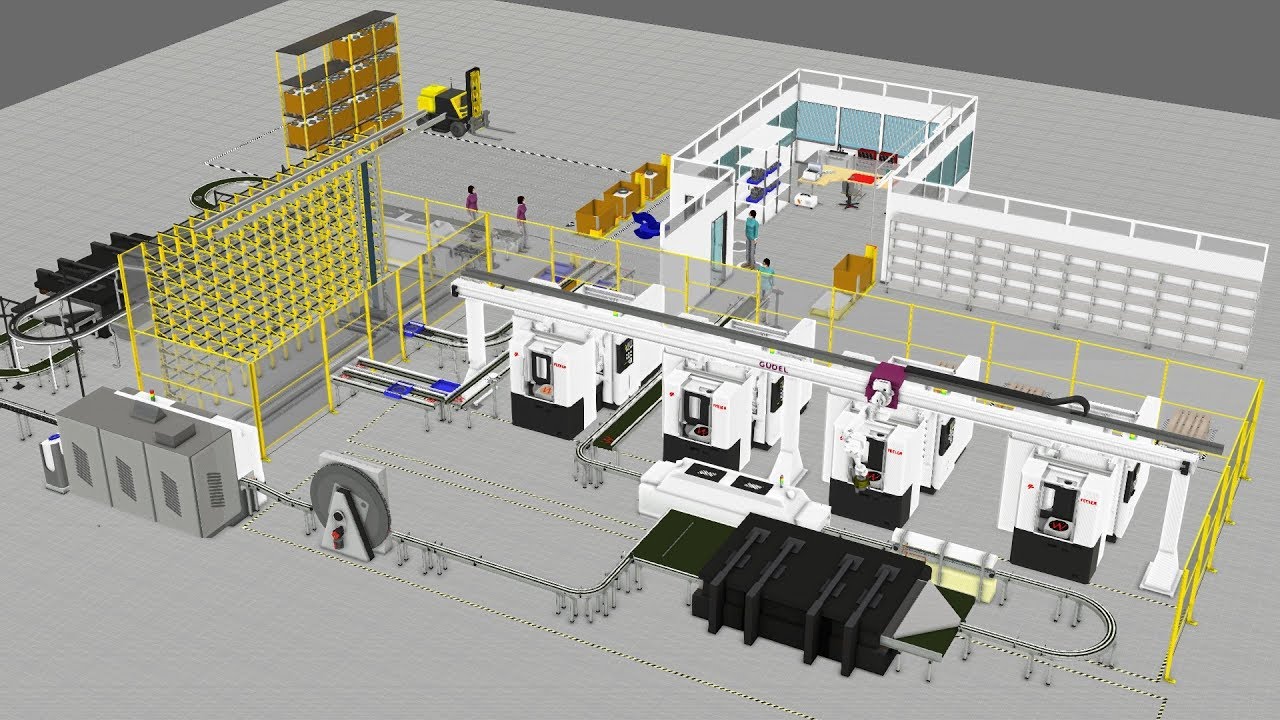

- Industrial Machinery & Robotics

- Consumer & Electronics

Why Choose Us

Our rigor, speed, and clear communication keep your programs moving—from early concept to release.

Validated models with defensible assumptions.

Efficient workflows to cut iteration time.

Recommendations balanced with manufacturability.

Transparent updates and design reviews.

Other Services

Explore our full range of engineering and product development services.

Modeling & Drafting

High-precision 3D models and clear 2D drawings for manufacturing and communication.

Learn MoreReverse Engineering

3D scanning to CAD reconstruction with upgrades for durability and manufacturability.

Learn MoreCAD Conversion & Migration

Digitize, standardize, and upgrade CAD data for consistency and future-ready workflows.

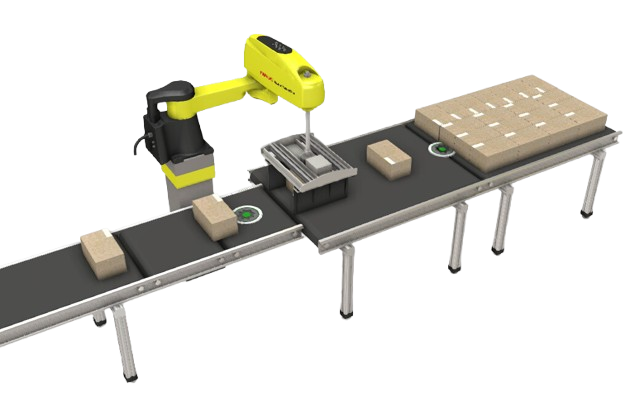

Learn MoreMachine Design

We design, engineer, and support customized machinery that meets your throughput, quality, and compliance targets.

Learn MoreTooling & Fixtures

Design and build of jigs, fixtures, and gauges for efficient, repeatable production.

Learn MorePLC Programming

Design and build of jigs, fixtures, and gauges for efficient, repeatable production.

Learn MoreReady to Simulate, Validate, and Optimize?

Share your requirements, constraints, and targets—we’ll propose a simulation plan with clear timelines and deliverables.

Talk to an Expert