Machine Design & Development

Achieving dependable throughput starts with a robust design. Our multidisciplinary team combines mechanical engineering, CAD expertise, and manufacturing know‑how to turn early ideas into production‑ready machines. We prioritize accuracy, serviceability, safety, and lifecycle cost—so equipment performs reliably from day one.

- Concept to commissioning under one roof

- Standards‑driven engineering documentation

- DFM/DFA reviews to reduce time and cost

- Iterative prototyping and validation

- Built‑in safety and maintainability

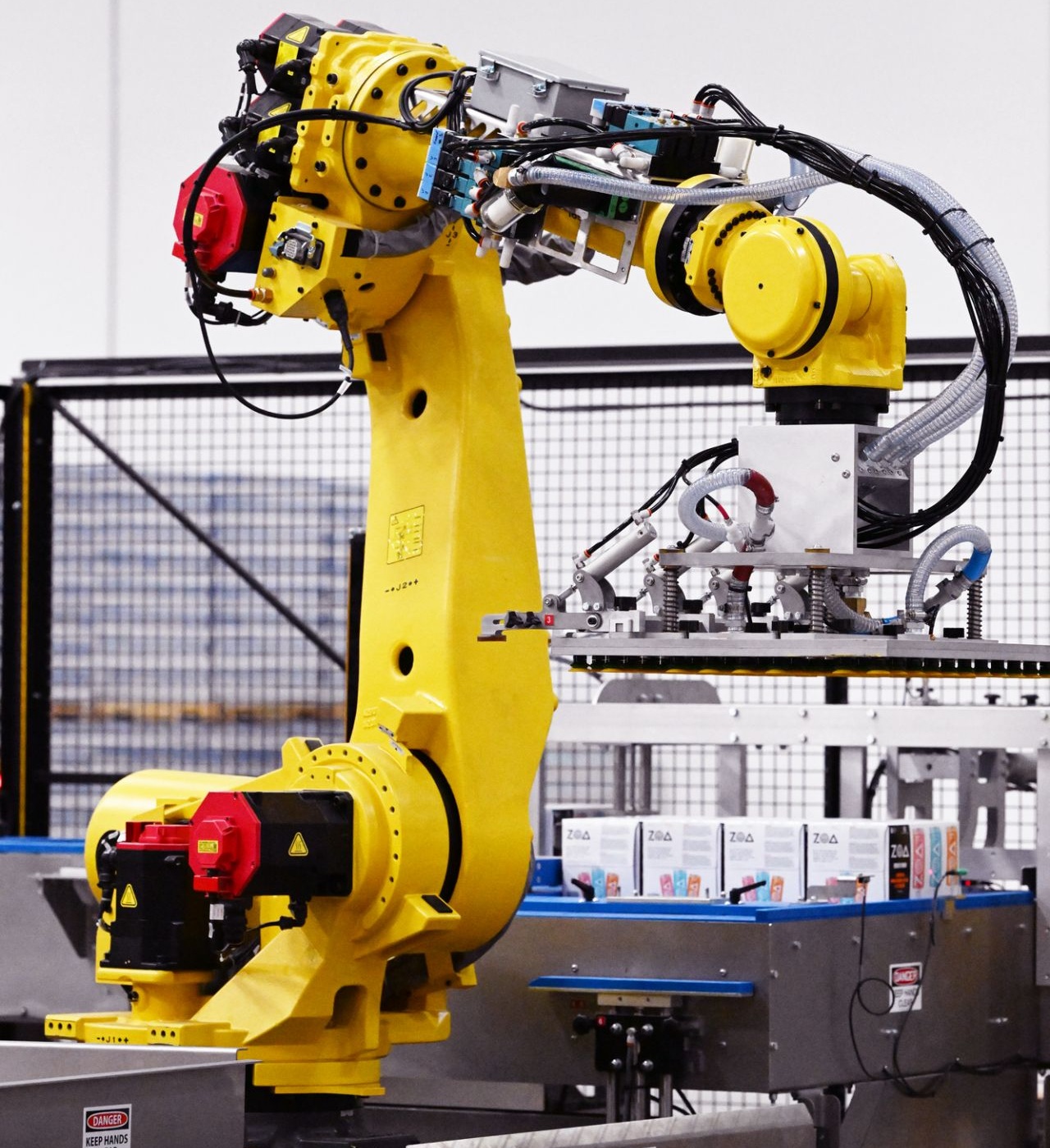

Core Capabilities

We design, engineer, and support customized machinery that meets your throughput, quality, and compliance targets.

Concept & Feasibility

Requirements capture, risk assessment, concept layouts, and feasibility studies to de‑risk early decisions.

Mechanical Design

Detailed CAD, mechanisms, frames, enclosures, motion and transmission elements, and tolerance stacks.

Engineering Docs

Manufacturing drawings, BOMs, assembly instructions, and maintenance manuals aligned to standards.

Prototyping & Testing

Rapid prototypes, fit‑checks, performance tests, and design refinements based on measurable results.

Build & Integration

Vendor coordination, fabrication support, assembly, and on‑site integration with existing lines or cells.

Commissioning & Support

FAT/SAT, operator training, spares, and preventive maintenance plans for long‑term reliability.

Our Design Process

We follow a structured, collaborative approach to deliver machines that hit performance targets with minimal iteration on the shop floor.

- Discovery: Define goals, inputs, constraints, and standards.

- Concept: Generate concepts, review trade‑offs, select direction.

- Detailing: 3D CAD, GD&T, materials, and component selection.

- Prototype: Validate critical risks; iterate design where needed.

- Build: Fabrication, assembly, safety checks, compliance.

- Commission: Test, tune, train, and handover with documentation.

Industries We Serve

We tailor each design to the demands of your sector, ensuring compliance, uptime, and scalability.

- Automotive & Components

- Electronics & Assembly

- Packaging & FMCG

- Industrial Machinery

- Aerospace & Precision

Why Choose Us

From early risk analysis to service manuals, we focus on details that save cost and downtime over the machine’s life.

Tight tolerances, robust frames, and repeatable motion.

Designed to your footprint, throughput, and budget.

Efficient workflows and supplier partnerships.

Responsive assistance from kick‑off to after‑sales.

Other Services

Explore our full range of engineering and product development services.

Modeling & Drafting

High-precision 3D models and clear 2D drawings for manufacturing and communication.

Learn MoreSimulation & Optimization

FEA/CFD studies with practical recommendations to improve performance and reliability.

Learn MoreCAD Conversion & Migration

Digitize, standardize, and upgrade CAD data for consistency and future-ready workflows.

Learn MoreReverse Engineering

3D scanning to CAD reconstruction with upgrades for durability and manufacturability.

Learn MoreTooling & Fixtures

Design and build of jigs, fixtures, and gauges for efficient, repeatable production.

Learn MorePLC Programming

Design and build of jigs, fixtures, and gauges for efficient, repeatable production.

Learn MoreReady to Build the Right Machine?

Share your brief, constraints, and targets—our engineers will propose an approach, timeline, and fixed deliverables.

Get a Proposal