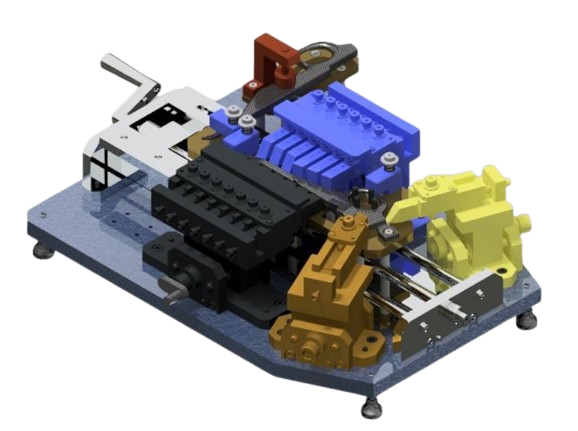

Tooling & Fixture Development

Improve throughput, quality, and repeatability with tooling engineered for your process. We design and build production‑ready fixtures, jigs, and gauges—balancing rigidity, ergonomics, safety, and cost—so operators can work faster with fewer errors and less rework.

- Concept-to-commissioning support

- Assembly, welding, machining, and inspection fixtures

- GD&T‑compliant locators and clamping schemes

- Detailed 2D drawings, BOMs, and 3D models

- Quick turnaround with robust QA

What We Deliver

Tailored tooling for new lines, upgrades, and continuous improvement—built for reliability and ease of use.

Assembly Fixtures

Datums, nests, and clamps designed to hold parts accurately and safely while maximizing operator access.

Machining & Welding Jigs

Rigid, repeatable setups for milling, drilling, turning, and welding—optimized for cycle time and quality.

Inspection Tooling

Go/No‑Go gauges, attribute and variable gaging, and CMM‑friendly fixtures aligned to your GD&T scheme.

Our Development Process

Early involvement reduces risk. We work alongside your manufacturing, quality, and safety teams from day one.

- Requirements: Review part CAD, tolerances, cycle time, and ergonomics.

- Concepts: Multiple fixture strategies with trade‑offs and risk notes.

- Detail Design: 3D CAD, locators, clamps, kinematics, and safety features.

- Build & Prove‑Out: Fabrication, assembly, and on‑line trials.

- Documentation: Drawings, BOM, setup sheets, and maintenance guides.

- Handover: Training, spare lists, and support for SOP integration.

Typical Deliverables

Everything needed to build, run, and maintain your tooling with confidence.

Engineering Package

2D drawings with GD&T, exploded views, assembly notes, and a structured BOM.

3D Models

Native CAD and neutral formats for CNC programming, reviews, and future changes.

Setup & QA Docs

Operator setup sheets, torque specs, inspection checklists, and maintenance plans.

Industries We Serve

Fixtures tailored to your parts, processes, and compliance standards.

- Automotive & Off‑Highway

- Aerospace & Defense

- General Manufacturing & Fabrication

- Electronics & Consumer

- Energy, Oil & Gas

Why Choose Us

We combine practical shop‑floor experience with rigorous engineering to deliver tooling that simply works.

Robust datum schemes and error‑proofing features.

Ergonomic designs that reduce changeover and takt time.

Standard components and clear service access.

Close coordination with production, QA, and EHS.

Other Services

Explore our full range of engineering and product development services.

Modeling & Drafting

High-precision 3D models and clear 2D drawings for manufacturing and communication.

Learn MoreSimulation & Optimization

FEA/CFD studies with practical recommendations to improve performance and reliability.

Learn MoreCAD Conversion & Migration

Digitize, standardize, and upgrade CAD data for consistency and future-ready workflows.

Learn MoreMachine Design

We design, engineer, and support customized machinery that meets your throughput, quality, and compliance targets.

Learn MoreReverse Engineering

3D scanning to CAD reconstruction with upgrades for durability and manufacturability.

Learn MorePLC Programming

Design and build of jigs, fixtures, and gauges for efficient, repeatable production.

Learn MoreNeed Fixtures that Boost Productivity?

Share part CAD, cycle time targets, and constraints—we’ll propose a fixture strategy, lead time, and budget.

Start Your Project