Professional Reverse Engineering

Recreate, refine, and future‑proof parts and assemblies with our end‑to‑end reverse engineering workflow. We capture complex geometries via 3D scanning, reconstruct precise CAD models, and apply engineering improvements to enhance durability, performance, and manufacturability.

- High‑accuracy 3D scan to CAD reconstruction

- Parametric, editable solid/surface models

- Design optimization and modernization

- Inspection reports and deviation analysis

- Documentation for manufacturing and QA

Why Reverse Engineering?

Recover design intent from legacy or undocumented parts, eliminate hidden flaws, and bring components up to current standards with reliable, manufacturable CAD.

Legacy Components

Rebuild discontinued or vendor‑locked parts.

Complex Geometry

Capture freeform shapes that are hard to measure.

Product Upgrades

Improve strength, weight, or service life.

Quality & Fit

Validate features against the source part.

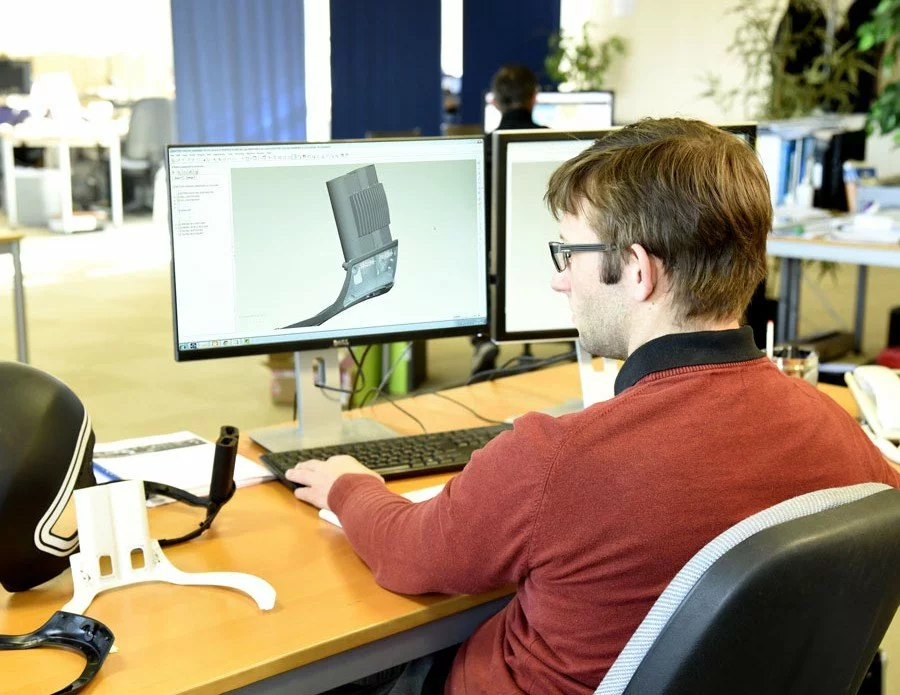

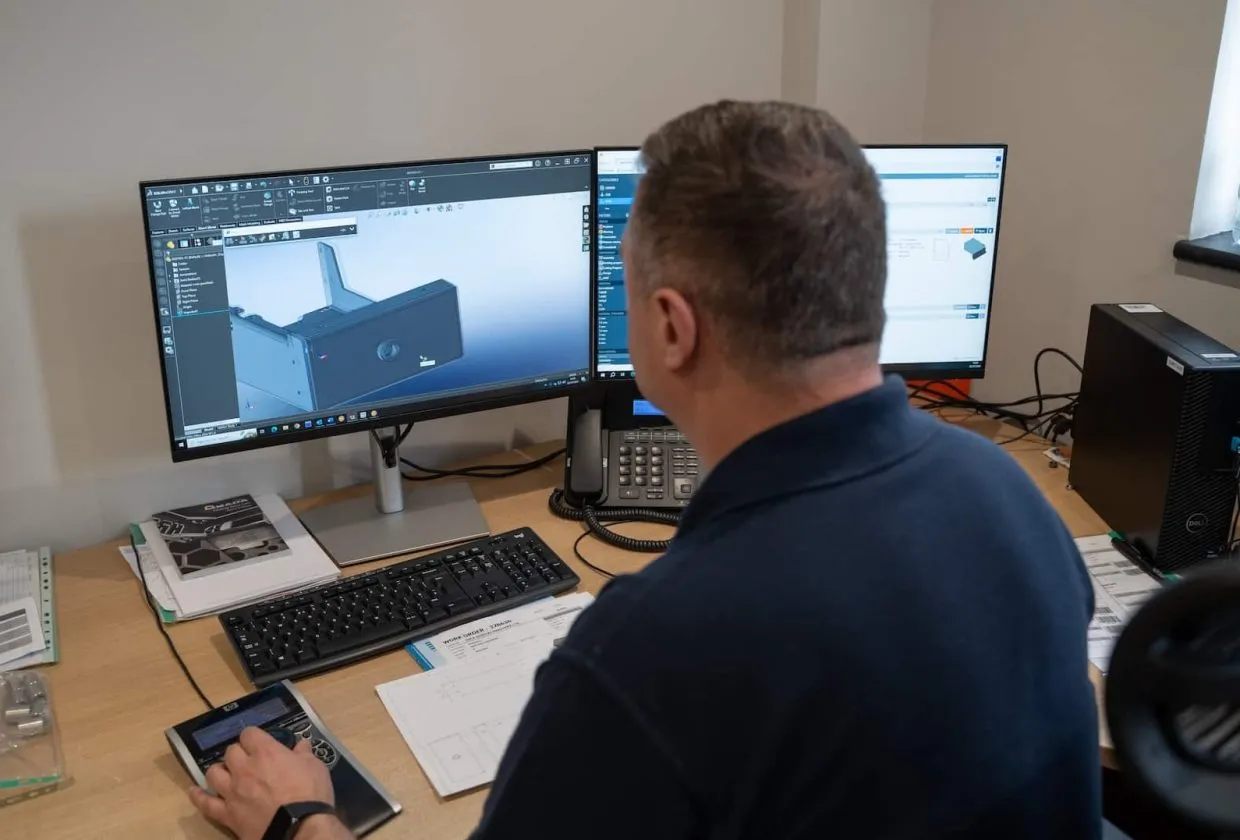

Our Reverse Engineering Process

A proven, traceable workflow ensures accuracy from the first scan to the final drawing set and inspection report.

- Assessment: Define goals, materials, tolerances, and critical features.

- 3D Scanning: Capture high‑resolution point clouds/meshes of the part.

- Data Processing: Clean, align, and segment the scan for reconstruction.

- CAD Reconstruction: Create parametric solids/surfaces with editable features.

- Verification: Deviation analysis and fit checks against the original.

- Documentation: Drawings, BOMs, and manufacturing notes for production.

Deliverables You Can Expect

We provide editable models, standardized drawings, and quality reports tailored to your toolchain.

Editable CAD Models

Parametric solids/surfaces in formats such as STEP, IGES, Parasolid, and native CAD on request.

Drawings & BOM

Manufacturing drawings with GD&T, material specs, finish, and a structured bill of materials.

Inspection Reports

Color‑map deviation plots and measurement summaries for QA and supplier validation.

Industries We Support

Our reverse engineering services power lifecycle extensions, cost‑downs, and redesigns across sectors.

- Automotive, Off‑Highway, and Rail

- Aerospace and Defense

- Industrial Equipment & Robotics

- Medical Devices & Consumer Products

- Energy, Oil & Gas, Utilities

Why Choose Us

Experienced engineers, standardized workflows, and clear documentation deliver reliable outcomes.

Metrology‑grade capture and verification steps.

Parametric models ready for quick changes.

Designs optimized for your processes and tooling.

From scanning to drawings, testing, and handover.

Other Services

Explore our full range of engineering and product development services.

Modeling & Drafting

High-precision 3D models and clear 2D drawings for manufacturing and communication.

Learn MoreSimulation & Optimization

FEA/CFD studies with practical recommendations to improve performance and reliability.

Learn MoreCAD Conversion & Migration

Digitize, standardize, and upgrade CAD data for consistency and future-ready workflows.

Learn MoreMachine Design

We design, engineer, and support customized machinery that meets your throughput, quality, and compliance targets.

Learn MoreTooling & Fixtures

Design and build of jigs, fixtures, and gauges for efficient, repeatable production.

Learn MorePLC Programming

Design and build of jigs, fixtures, and gauges for efficient, repeatable production.

Learn MoreNeed to Reproduce or Improve a Part?

Share your component, target specs, and required formats—we’ll provide a clear plan, timeline, and deliverables.

Start Your Project